Shipbuilding and the modern contest for sea dominance - Part 1

Introduction

The history of civilization is inextricably linked to the history of the ship. The capacity to build vessels capable of traversing water has, from the earliest human endeavors, been a fundamental driver of trade, migration, warfare, and the projection of power. This foundational relationship between shipbuilding technology and geopolitical influence demonstrates that control of the seas has always been rooted in the ability to build superior ships. From the first reed boats that plied ancient rivers to the riveted ironclads that heralded a new age of industrial warfare, the evolution of the shipyard is a direct reflection of humanity’s ambition to master the maritime domain.

The Dawn of Maritime Endeavor (8000 BC - 1450 AD)

The human drive to cross water is an ancient imperative, predating many of the foundational technologies of settled civilization. The oldest known physical boat, the Pesse canoe found in the Netherlands, has been carbon-dated to a period between 8040 and 7510 BCE, revealing that sophisticated woodworking for water travel existed at the dawn of the Holocene epoch. Yet, inferential evidence suggests even earlier maritime capabilities. The settlement of Australia approximately 50,000 years ago would have required an open-sea voyage of over eighty kilometers, a feat impossible without some form of seagoing craft. These early ventures were not merely for exploration or migration but were quickly adapted for economic purposes. By the 7th millennium BCE, an unknown Neolithic people were engaged in the seaborne trade of high-value obsidian across the Aegean Sea, establishing the first known maritime trade routes.

Early shipbuilding was a global phenomenon of adaptive problem-solving, with techniques and materials dictated by local resource availability and environmental necessity. This was not a simple, linear progression toward a single “best” method but a diverse tapestry of innovation.

Reed and Raft Construction

In regions rich in reeds but poor in large timber, civilizations developed buoyant watercraft from bundled plants. Around 4000 BC, ancient Egyptians began building sailing boats from papyrus reeds for transport on the Nile River. These early vessels, depicted on vases and in graves, were long, narrow, and propelled by paddles. Similarly, Mesopotamian cultures in the Persian Gulf constructed sailing vessels from bundled reeds coated in bitumen around 3500 BCE, enabling them to engage in maritime trade with Neolithic Arabian cultures.

The reed boat Ra II

The reed boat Ra IISkin-on-Frame Construction

In the wood-scarce environments of the Arctic and subarctic, peoples developed skin boats by stretching animal hides over frames of wood or bone. These craft, including kayaks and umiaks, were lightweight, resilient, and perfectly adapted to their harsh surroundings.

Inuit kayak

Inuit kayakShell-First Wood Construction

The dominant paradigm for wooden shipbuilding in this era was the “shell-first” method, in which the watertight outer hull was constructed before the internal framework was added. This approach prioritized the most critical engineering challenge: creating a viable barrier against the water. Several key techniques emerged:

Sewn and Lashed Planks: Planks were literally “sewn” together using rope passed through drilled holes. This technique, found worldwide, created a highly flexible hull capable of withstanding the stresses of heavy surf and beaching. The famous Abydos boats of Egypt, dating to 3100 BC, were constructed using this method, with woven straps lashing the planks together and grass stuffed in the seams for sealing.

Sewn and Lashed Planks construction technique

Sewn and Lashed Planks construction techniqueMortise-and-Tenon Joints: A more rigid and complex technique, originating among the seafaring nations of the Mediterranean, involved fitting wooden pegs (tenons) into carved slots (mortises) on the edges of adjoining planks. This created a strong, unified hull, essential for the galleys used by the Greeks and Phoenicians for both trade and warfare.

Mortise-and-Tenon Joints construction technique

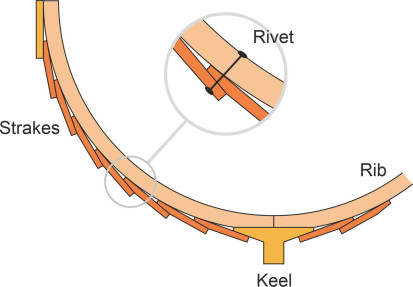

Mortise-and-Tenon Joints construction techniqueClinker Construction: Developed in Northern Europe, the clinker (or lapstrake) technique involved overlapping hull planks and fastening them with iron rivets. This method, famously employed by the Vikings for their longboats around 1000 AD, produced a hull that was simultaneously lightweight, strong, and flexible. This unique combination allowed Viking longboats to function as peerless amphibious assault craft, capable of crossing the open North Sea and then penetrating deep into continental Europe via shallow rivers.

Clinker Construction method used by Vikings

Clinker Construction method used by VikingsThese technological advancements directly enabled the expansion of trade networks, large-scale migrations, and the projection of military power. The Phoenicians used their man-powered galleys, armed with rams and archers, to dominate Mediterranean trade and warfare, establishing commercial routes as far as Cornwall in search of tin. The Austronesian expansion, which began around 3000 BC, stands as one of history’s greatest maritime migrations. Propelled by sophisticated sailing technology, including outrigger canoes and crab claw sails, Austronesian peoples spread from Taiwan across Southeast Asia and into the vast Pacific, settling remote islands like Hawaii and New Zealand. In the East, Chinese junks, appearing around 1100 AD, represented a leap in naval architecture. They featured innovations such as stern-mounted rudders for steering, watertight compartments to prevent sinking, and battens on their sails for increased strength - technologies that would not appear in Western ships for centuries.

The Age of Sail and the Rise of Global Empires (1450 - 1840)

The Age of Sail marked the period when the shipyard became a strategic national asset and the vessels it produced became the primary instruments of global power. Advancements in ship design and construction, centered in Europe, were the technological key that unlocked long-distance exploration, colonization, and the creation of the first truly global trade empires.

A pivotal technological shift was the adoption of carvel construction, where hull planks were laid edge-to-edge over a pre-erected frame, creating a smooth surface. This method, which replaced the overlapping clinker style of Northern Europe, allowed for the construction of significantly larger and more robust hulls. These stronger frames could support multiple decks and, crucially, mount rows of heavy cannons, transforming the ship from a mere transport vessel into a formidable weapon of war.

Carvel construction technique with edge-to-edge planking

Carvel construction technique with edge-to-edge plankingThis innovation gave rise to the signature vessels of the era:

Carracks and Caravels: These three- and four-masted ships were the workhorses of early exploration. They combined the powerful, square-rigged sails of Europe with the versatile, triangular lateen sails of the Arab world, enabling them to sail effectively both with and against the wind on long oceanic voyages.

16th-century carrack warship Henry Grace à Dieu

16th-century carrack warship Henry Grace à DieuGalleons and Ships-of-the-Line: As imperial competition intensified, these vessels evolved into multi-decked, heavily armed warships. The galleon became the backbone of the Spanish Empire’s treasure fleets, while the “ship-of-the-line,” a floating fortress carrying 70 to 100 cannons, established the dominance of the British Royal Navy.

Ship-of-the-line, the dominant warship of the Age of Sail

Ship-of-the-line, the dominant warship of the Age of SailWith these new designs, shipbuilding transformed into a complex, large-scale industrial enterprise. Shipyards became noisy, hectic hubs of activity, employing hundreds of men working on multiple vessels simultaneously. The construction process itself was a blend of established principles and artisanal skill. In the absence of detailed architectural plans, master shipwrights relied on experience and techniques like “whole moulding,” using full-scale wooden patterns to trace shapes directly onto timber. Construction was a monumental, manual undertaking. It began with the laying of a massive keel, often hewn from a single giant tree. The stempost and sternpost were then attached, and the ship’s ribs - too massive to be bent - were painstakingly carved from naturally curved timbers and assembled from multiple pieces known as futtocks.

Access to strategic materials, particularly high-quality timber, became a matter of national security. Oak was the preferred wood for its strength and durability in ship frames, while tall, straight-grained pine was essential for masts and spars. The vast, untapped forests of the American colonies provided a decisive advantage, first to the British Empire and later to the United States. The unique properties of American live oak, found in the southern colonies, were especially prized - its density and resistance to rot gave Carolina-built ships an average lifespan of 20 to 30 years, nearly double that of their European-built counterparts.

As navies became the central pillar of state power, governments began to exert direct control over shipbuilding. This process reflects the broader development of the modern bureaucratic state, where key instruments of power were rationalized and brought under central authority. The shipyard was no longer just a workshop but an extension of the state’s strategic and financial apparatus. In Britain, administrators like Samuel Pepys in the late 17th century championed the creation of “Establishments,” which were detailed regulations that standardized the dimensions, armament, manning levels, and tonnage for each class of warship.

Samuel Pepys, English naval administrator who standardized shipbuilding

Samuel Pepys, English naval administrator who standardized shipbuildingThe primary motivation was not purely technical but administrative and financial: to create a predictable budget for Parliament and a standardized force that could be reliably maintained and deployed. This institutionalization of design turned the warship into a fungible tool of national policy and intensified geopolitical competition. National strategies became reflected in ship design philosophies: French ships were often built with lighter timbers for speed, excelling in commerce raiding, while British ships were heavily timbered for durability, designed to withstand the brutal punishment of fleet-on-fleet battles. The expertise of shipwrights became a valuable commodity, with nations like Spain actively recruiting English and Irish masters to bolster their own shipbuilding capabilities.

The Industrial Revolution - The Supremacy of Steam and Steel (1840 - 1914)

The 19th century witnessed the most profound technological revolution in maritime history, as millennia of reliance on wood and wind gave way to the dominance of iron, steel, and steam. This transformation was not merely an upgrade but a fundamental paradigm shift that fused shipbuilding with heavy industry. Sea power became a direct function of a nation’s industrial capacity, setting the stage for a new form of geopolitical competition that would culminate in the First World War.

Materials

The first revolution was in materials. For centuries, the size of wooden ships was constrained by the inherent limitations of timber, they could not be built much longer than 80 meters, and their bulky internal frames consumed valuable cargo space. The Industrial Revolution, with its advances in metallurgy, provided the solution.

The Iron Age: Wrought iron became available in large quantities, enabling the construction of larger, stronger, and more durable hulls. The visionary engineer Isambard Kingdom Brunel’s SS Great Britain, launched in 1843, was the first ocean-going vessel built entirely of iron. It proved the superiority of the new material, offering greater cargo capacity and requiring far less maintenance than its wooden predecessors.

:max_bytes(150000):strip_icc()/SS-Great-Eastern-3000-3x2gty-56a489eb3df78cf77282dedd.jpg) SS Great Britain, the first iron-hulled ocean-going ship

SS Great Britain, the first iron-hulled ocean-going shipThe Steel Age: By the 1880s, steel began to supplant iron. It was stronger, more resilient, and could be produced more consistently, allowing for even larger and more robust ship designs. This transition was made possible by earlier breakthroughs, such as Henry Cort’s 1784 patent for the “puddling” process, which produced high-quality malleable wrought iron and laid the groundwork for the mass production of steel.

Propulsion

Concurrent with the material revolution was the revolution in propulsion.

Early Steam: The first practical steam engines were applied to ships in the early 1800s. The Charlotte Dundas (1801) was a pioneering steam-powered tug, but like other early steamships, it used inefficient and vulnerable paddle wheels, which were ill-suited for rough seas.

Charlotte Dundas, an early steam-powered tugboat

Charlotte Dundas, an early steam-powered tugboatScrew Propeller: The widespread adoption of the screw propeller from the 1840s onward was the critical breakthrough. Submerged and more efficient, the propeller, when paired with an iron hull and a powerful steam engine, created the modern steamship.

Screw propeller of the SS Archimedes

Screw propeller of the SS ArchimedesThe shift from sail was not immediate. Early steam engines were notoriously inefficient, consuming vast quantities of coal that severely limited their range. For several decades, most steamships were hybrids, retaining a full set of sails for long-distance voyages, with the engine used as an auxiliary power source or for navigating in calm winds.

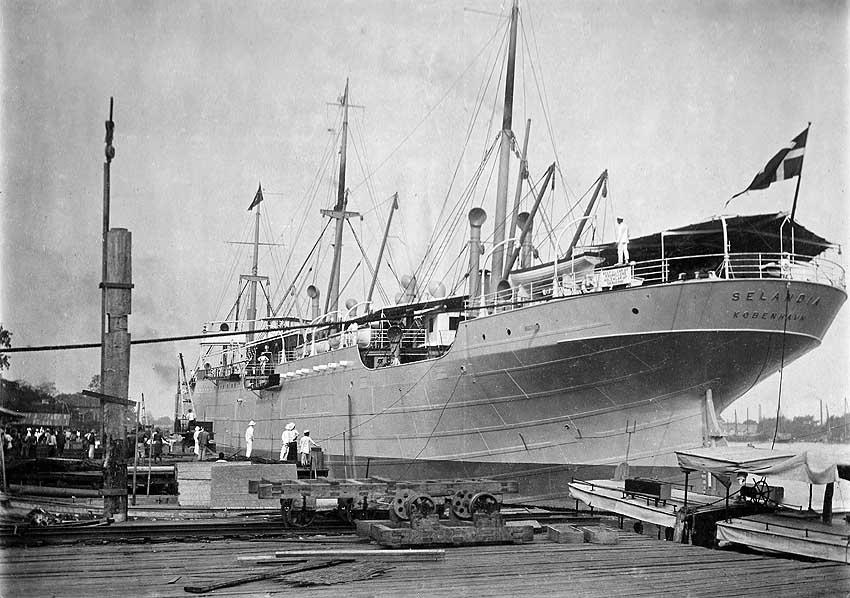

Diesel Power: The final step in this propulsion revolution came around 1910, as ships began converting from coal-burning steam plants to more efficient and powerful diesel engines that burned oil. This greatly increased operational range, reduced the number of crew needed to stoke boilers, and marked the true end of the commercial age of sail.

MS Selandia, first fully diesel-powered ship 1912

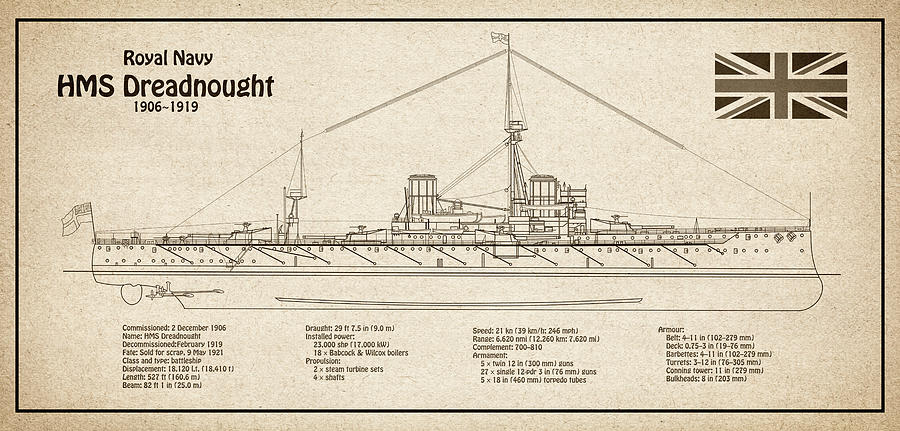

MS Selandia, first fully diesel-powered ship 1912The convergence of these industrial technologies - steel hulls, steam turbine engines, and advanced gunnery - led to a geopolitical climax in 1906 with the launching of the British battleship HMS Dreadnought. With its all-big-gun armament and unprecedented speed, this single vessel was so revolutionary that it rendered every existing battleship in the world obsolete. This technological disruption effectively reset the global naval balance of power, nullifying Britain’s massive numerical advantage in older “pre-dreadnought” ships and creating a strategic opening for its primary industrial rival, Germany.

HMS Dreadnought ship plans - the revolutionary battleship of 1906

HMS Dreadnought ship plans - the revolutionary battleship of 1906The result was the Anglo-German Naval Arms Race, a conflict fought not at sea but in the shipyards, steel mills, and national treasuries of the two empires. Germany, guided by Admiral Alfred von Tirpitz, saw an opportunity to challenge Britain’s long-held maritime supremacy by competing on a new, level playing field. Britain, whose national security and economic prosperity were underwritten by its “two-power standard” (a navy larger than the next two largest navies combined), was forced to respond.

The ensuing race was a direct contest of industrial might: which nation could produce these complex, resource-intensive machines faster and in greater numbers? It became a measure of national steel production, engineering capacity, and, most importantly, the political will to allocate immense financial resources to naval construction.

This period demonstrated conclusively that modern sea power was no longer simply a matter of maritime tradition or seamanship - it was a direct and brutal calculus of a nation’s total industrial and economic power.